Department of Steels

- Head of Department

Lee, Chang-hoon

Department Introduction

Department of Steels is focusing our efforts to create innovative technical solutions for the development of high value-added steels in cooperations with steelmaking companies as well as research institutes. With the goal of promoting cutting-edge technologies, the research works performed at Department of Steels cover the important area of steel research to achieve the optimization of alloy design, process/property control, and precision analysis technologies.

Major Activities

- Development of leanized duplex stainless steels having high corrosion resistance: 3 papers published, 1 patent registered, 1 PCT, 1 software registered

- Development of lightweight steels and lightweight stainless steels: 6 papers published, 3 patents registered

- Development of reduced activation ferritic/martensitic steel for fusion reactor: 8 papers published, 2 patents applied

- Development of fire and seismic resistant steels: 1 paper published, Gilbert R. Speich Award (AIST Metallurgy Technology Division)

- Development of neutron shielding stainless steels: 7 papers published, 2 patents registered, 6 patents applied

- Software for prediction of mechanical properties of steel based on artificial neural network modeling: 9 softwares registered, CDE DX Awards 2021, Rescale & AWS Special Award (University/Research Institute)

Major Research Area

- Leanized stainless steels using interstitial alloy elements such as C and/or N

- Lightweight steels and stainless steels

- Reduced activation ferritic/martensitic steels for fusion reactor

- Fire and seismic resistant steels

- Neutron shielding stainless steels

- Steel property prediction techniques using AI

Future Research Plan

- Commercialization research on leanized stainless steels

- Commercialization research on lightweight steels and stainless steels

- Development of high toughness section steels for offshore structure

- Development of reduced activation ferritic/martensitic steel for fusion reactor

- Development of advanced heat resistant steels for future plants

- Development of steel property prediction technologies using AI

Major R&D Activities

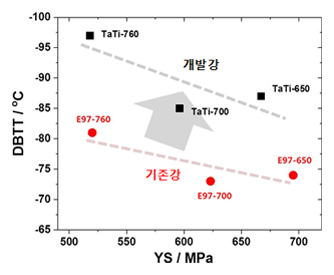

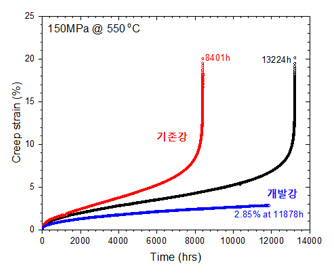

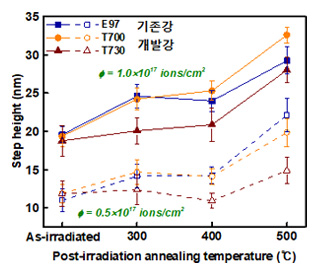

Development of reduced activation ferritic/martensitic (RAFM) steel for fusion reactor

- Development of Ta and Ti added RAFM steel through neural network modeling and thermodynamics calculation

- Improvement of tensile and Charpy impact properties and creep property due to precipitation of (Ta,Ti)X particles and refinement of M23C6 carbides by adding Ta and Ti

- Improvement of irradiation embrittlement and He swelling resistance

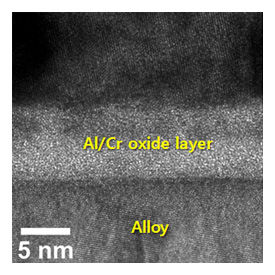

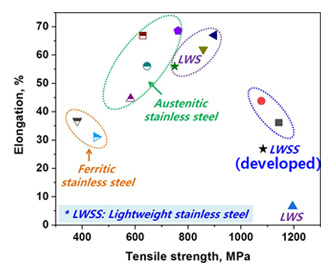

Development of lightweight stainless steel

- Development of lightweight stainless steel with approximately 20% weight reduction by adding 12 wt.% of Al

- Improvement of corrosion resistance due to a dense Al/Cr oxide layer by optimizing Cr content

- Excellent combination of strength and elongation compared to conventional stainless steels

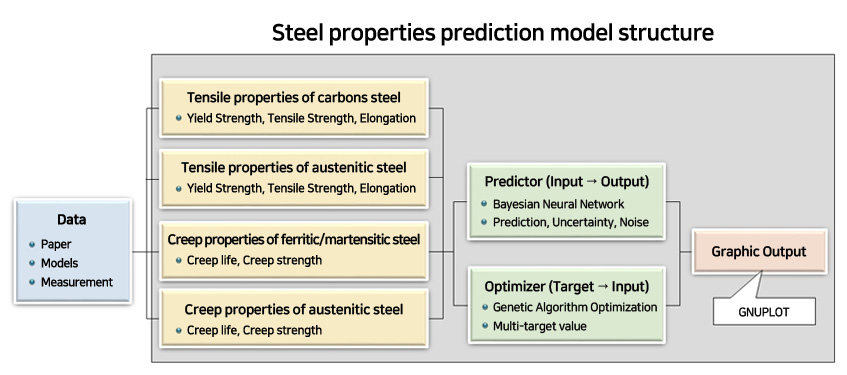

Software for prediction of mechanical properties of steel based on artificial neural network

- Development of mathematical models that automatically predict major mechanical properties based on process parameters for designing and optimization of steel production process.

- Prediction of tensile properties of carbon steel, tensile properties of austenitic stainless steel, creep properties of ferritic/martensitic heat-resistant steel, and creep properties of austenitic heat-resistant steel.

- Evaluation and visualization of predicted values, model uncertainty, and noise.

- Input parameter optimization to achieve multi-target results