Department of Aluminum

- Head of Department

Kim, Su-hyeon

Department Introduction

Aluminum Department is in charge of conducting research and development on aluminum alloys and their optimized applications to vehicle materials to improve fuel efficiency and driving performance. The research area focused in the department is development of high-performance aluminum alloys covering the fields of alloy design, microstructure control, low-cost energy-efficient processing, and fabrication techniques.

Major Activities

- Development of twin-roll casting process of aluminum alloys and components for automotive and mobile electronics applications : 1 domestic patent applied, 1 international patent registered, 3 million KRW of technology transfer, 1 follow-up project

- Development of high-performance aluminum casting alloys by ultrasonic melt treatment : 2 papers published, 1 domestic patents registered

- Electromagnetically melt-treated multicomponent high-strength aluminum alloys : 3 papers published

- Development of fabrication processes of high energy absorbing aluminum form : 1 paper published, 1 domestic patent registered

Major Research Area

- Improvement of critical properties in castings based on melt treatment

- Development of high-strength, high-ductility, non-heat-treated aluminum alloys for diecasting

- High strength and high thermal conductivity alloys and simultaneous improvement of strength and elongation through microstructure control

- Low-cost fabrication process of high strength aluminum alloy sheets and components for automotive and mobile electronics applications

- High strength extrusion/casting alloys for electric vehicle chassis parts

- High strength and high heat stability aluminum alloy based on interface-controlled nano-precipitates

Future Research Plan

- Aerospace aluminum sheet alloys

- Giga-strength aluminum alloys by multi-scale complex precipitates with externally applied energy

- Development of an innovative aluminum technology for shielding a large capacity and high voltage xEV generator

- Non-heat-treatable aluminum alloys for thin-walled, large area near-net-shape diecasting

- Precipitation-strengthened high-strength heat-resistant aluminum alloys

- Materials and shape design of energy-absorbing aluminum alloy components

- Optimization technology for alloys and processes using machine learning and virtual alloy design platform with reliable aluminum casting material database

Major R&D Activities

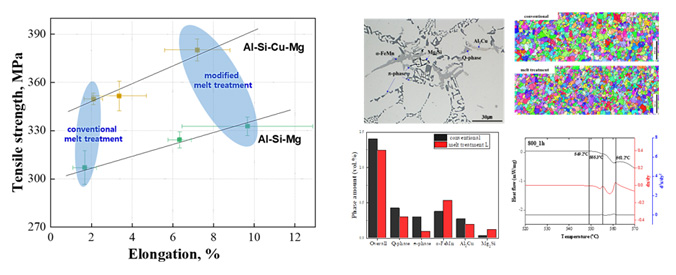

Improvement of the mechanical properties of aluminum cast alloys via the melt treatment process

[Objective]

- Design of the melt treatment process in consideration of the liquid structure control, and the application of the process to improve the strength/ductility of the Al-Si-(Cu)-Mg cast alloy

[Results]

- Design of melt treatment process and alloying elements suitable for liquid structure control

- Analysis of microstructures with melt treatment for Al-Si-(Cu)-Mg alloys

- Simultaneous improvement of strength and ductility of Al-Si-(Cu)-Mg alloys via suitable melt treatment process

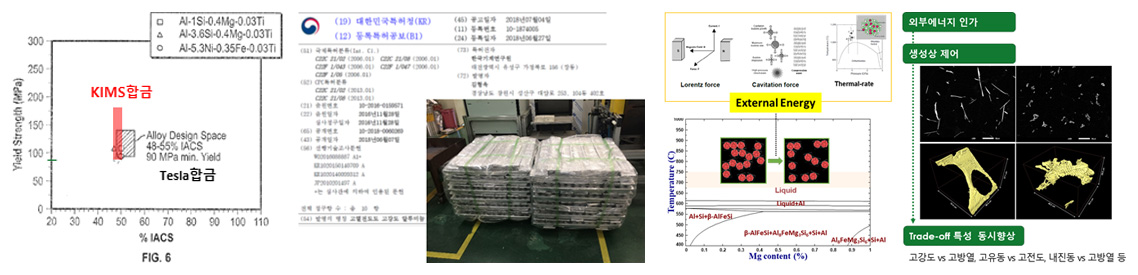

Aluminum casting alloys with high strength/conductivity

[Objective]

- Development of a new aluminum casting alloy with high strength and high thermal conductivity for its application to xEV enclosures requiring strength/conductivity trade-off

- A novel process of Fe-rich intermetallics modification for the improvement of ductility/strength/conductivity trade-offs and the recyclability

[Results]

- Development of low Si aluminum casting alloys with high thermal conductivity, 200 W/mK and high yield strength, 180 MPa (KIMS owned technology)

- Improvement of strength/conductivity trade-off through controlling constituent phases in aluminum casting alloy (1 domestic patent application)

- A feasible process developed to improve the tolerance level of Fe impurities in Al-Si casting alloys for 100% recyclability

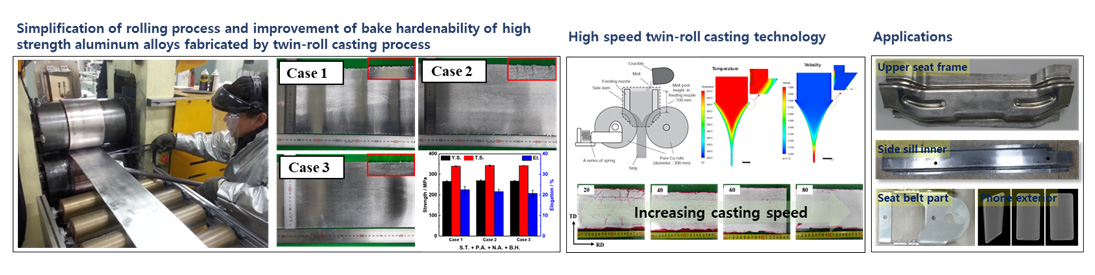

Development of high strength aluminum alloy sheets and components for automotive and mobile electronic applications

[Objective]

- Development of aluminum alloy sheets for automotive and mobile electronic applications by utilizing twin-roll casting and follow-up process to reduce manufacturing cost.

[Results]

- Optimization of thermo-mechanical process of 6XXX/7XXX series high-strength aluminum alloy sheets for automotive applications

- Development of high-speed twin-roll casting process to promote productivity of aluminum sheets for automotive applications

- Development of automotive and mobile electronic components using high strength aluminum alloys sheets fabricated by twin-roll casting process