Department of Titanium

- Head of Department

Park, Chan-hee

Department Introduction

Titanium is a key material in the energy, power generation, defense, aerospace, and medical industries. Titanium department is focusing our efforts to self-reliance and high value-added titanium materials that depend on 90% overseas, and developing titanium parts manufacturing technology using carbon-reducing titanium scrap recycling technology.

Major Activities

- 2021 Titanium Technology Workshops (2021/08/26)

- Titanium Symposiums in 2020 KIM Spring & Fall conference

- Technology transfer related to “New TiAl alloy for gas turbines”, Etc. (9, total 221 million KRW)

- Research on Ti alloys (24 SCI papers, 13 patents)

Major Research Area

- Titanium blade manufacturing technology for power generation parts.

- Titanium additive manufacturing process technology

- Development of free-cutting titanium

- Manufacturing technology of high-strength and super-elasticity Titanium thin plate

Future Research Plan

- Ti-Mo alloy design for biomedical purposes.

- Manufacture technology of titanium alloy for medium and high temperature

- Recycling of rare metals and development of manufacturing technology

- Manufacture technology of titanium materials for electronic devices

Major R&D Activities

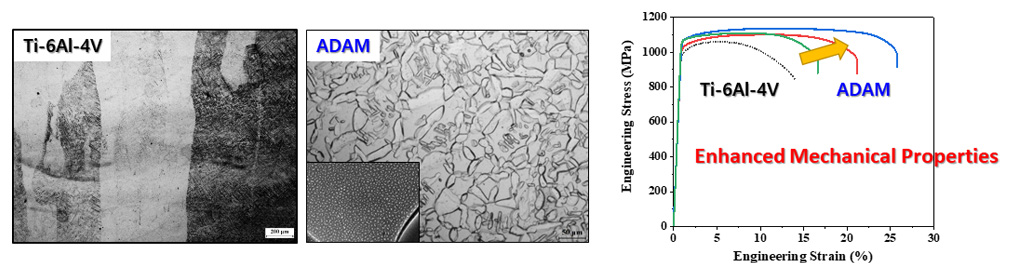

Titanium Alloy Design for Additive Manufacturing

- Enhanced microstructural homogeneity of additively manufactured titanium alloys by alloy development.

- Thermodynamic calculation and experimental investigation of second phase particles in ADAM Titanium alloys.

- Alloy design with Artificial Neural Network.

- Process optimization for the additive manufacturing process, post heat treatment.

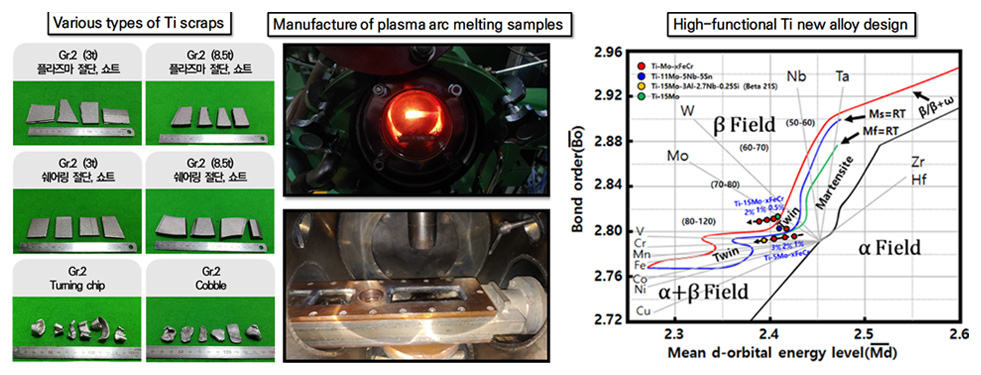

Development of high-functional titanium alloy for medical & consumer application

- Evaluation of microstructure and mechanical properties for advanced companies' high-functional titanium alloy billets and hot rolling materials.

- Among the titanium scraps of various types, the type of titanium scrap that is most suitable for plasma arc melting was selected through plasma arc melting tests and mechanical properties evaluation.

- Design and test verification of high-functional titanium new alloy for biomedical applications and consumer goods using selected titanium scraps as raw materials and plasma arc melting process.

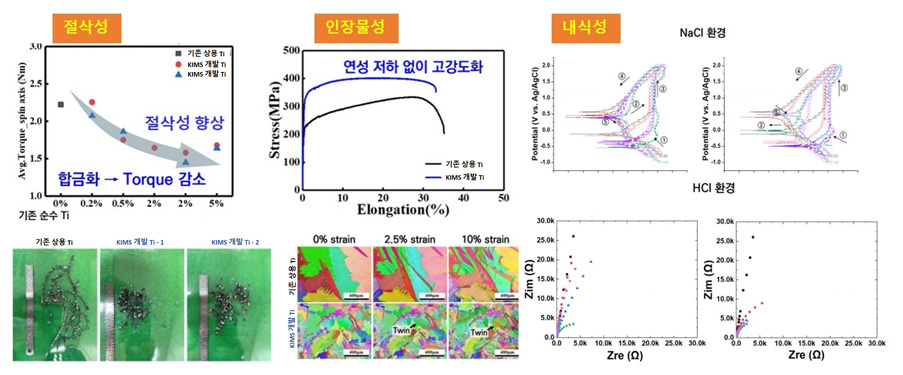

Development of free-cutting titanium

- Development of free-cutting titanium with improved machinability by more than 30%

- Development of microstructure modification enabling high strength and ductility

- Demonstration of corrosion resistance of developed free-cutting titanium