Department of Electrochemistry

- Head of Division

Lee, Joo-Yul

Department Introduction

Department of Electrochemistry develops wet-process-based surface treatment technology of nano-structured functional materials and electrodeposition technology for various applications such as electronic devices, sensors, dental implants, solar, and fuel cells. Also, we develop novel computational and experimental electrochemical techniques not only for electroplating but also for electroforming, electroless plating, chemical conversion coating, anodizing, etching, and electropolishing, etc.

Major Activities

- Development of electrolyte monitoring for copper electroplating and cathode materials : 3 papers published, 1 patent applied.

- Development of functional precision electroplating and surface treatment : 5 papers published, 2 patents applied, Royalty : 50 million KRW

- Development of Anodic oxide film with improved corrosion resistance : 3 papers published, royalty : Royalty (20 million KRW)

- Development of ion-selective electrode and other sensors : 2 papers published.

Major Research Area

- Electroplating for electronic, electrocatalyst, and battery applications

- Materials, electrodes, and devices for energy conversion system (thermoelectric material, catalyst, current collector)

- Electrochemical sensor (chemical and corrosion sensor)

- Anodizing and plasma electrolytic technologies for aluminum, magnesium and titanium alloys

- Development of electroplating with ionic liquids

- Modeling and simulation for electroplating

Future Research Plan

- Eco-friendly, and zero-emission surface treatment

- Process monitoring for smart electroplating factory

- Design for electroplating process based on a computational simulation

- Anodic oxide film formation on aluminum and magnesium alloys for improved corrosion resistance

- Development of metal/polymer joining technology

Major R&D Activities

Development of 30㎛ ceramic beads and reliability evaluation technology

[Introduction]

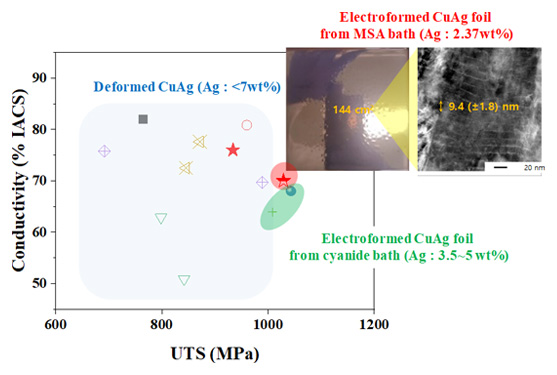

- Development of metal sheet with high strength/high electrical conductivity for fine-pitch probe pin

[Contents and Results]

- Development of nano-multilayered CuAg foil (16 um) using electrodeposition in environmental-friendly bath

- Process optimization to achieve high tensile strength (>1GPa), and high electrical conductivity (~70%IACS)

- Achievement of thermal stability

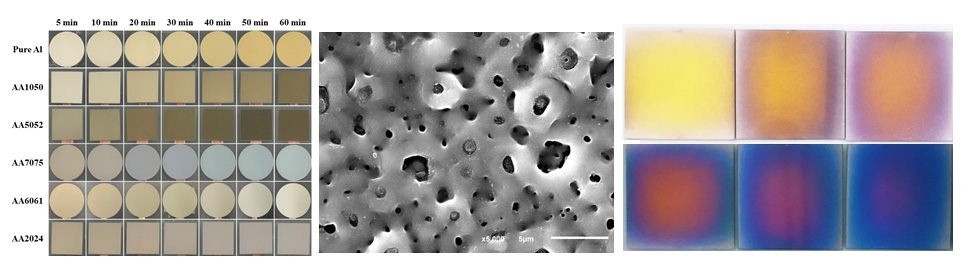

Development of anodic oxide films on Al and Mg alloys for improving dielectric breakdown property and corrosion/abrasion resistance and for coloring

[Introduction]

- Anodic coatings on Al and Mg alloy for improving dielectric breakdown voltage and abrasion resistance and coloring of Al by using anodic oxide film and Au nano-coating layer

[Contents and Results]

- Coating of anodizing films on Al alloys for high corrosion resistance and withstand voltage

- Coating of PEO films on Al alloys for high abrasion resistance

- PEO film formation technology on Mg alloys for improved corrosion resistance

- Coloring of Al alloys using barrier type of anodic oxide film and Au nano-coating