Department of Authorized Nuclear Inspection

- Head of Department

Lee, Sang-hoon

Department Introduction

Department of Authorized Nuclear Inspection was approved from Korean government(Ministry of Science and Technology) in 1993 and was accredited and certified as Authorized Nuclear Inspection Agency by KEA(Korea Electric Association) in 1997. Authorized Nuclear Inspection(ANI) is one of the most important functions in ensuring the safety of nuclear power plant(NPP). To ensure the safety of NPPs, ANI verifies that the Owner properly manufactures and installs the safety class components and constructs concrete containment according to the approved Code & Standards, and also confirms that the integrity of safety class components and concrete containment is continuously maintained during operation.

Major Activities

- Authorized inspection for manufacturing of the safety class components (2 certificate holders inspection who fabricates safety class items such as pumps, valves, etc.)

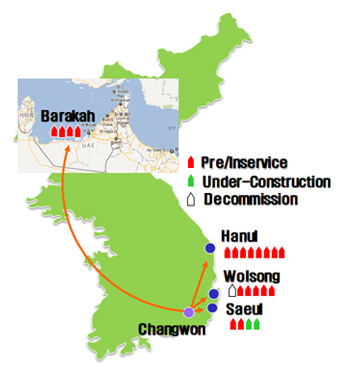

- Authorized inspection for construction of NPP (ShinHanul #1·2, UAE BNPP #1·2·3·4, ShinKori #5·6)

- Authorized inspection for pre/in service inspection (15 NPP units in Korea and pre/in service inspection for UAE BNPP #1·2·3·4)

| Domestic NPP | Manufacturing |

|

|

|---|---|---|---|

| Construction |

|

||

| Pre/inservice inspection |

|

||

| Foreign NPP (UAE) | Manufacturing & Construction |

|

|

| Pre/inservice inspection |

|

Education and training for the engineers in nuclear power industry

| Date | Education Title | Enrolment |

|---|---|---|

| 6/24 | The technical academy for the engineers in post tensioning system | 22 |

| 8/19 | The technical academy for the engineers in nuclear power industry | 20 |

Major Research Area

- Authorized nuclear inspection (Manufacturing, Construction, Pre/in service inspection)

- Education and training for engineers in nuclear power industry

- Technical supports for nuclear power industry

Future Research Plan

- Development of training course for reinforced concrete and the post-tensioning system

- Technical support for small and medium-sized company related to nuclear power industry

- Technical support for KEPIC certificate

- Research and development for authorized nuclear inspection technology

Major R&D Activities

Safety enhancement of nuclear power plants through Authorized Nuclear Inspection(ANI)

[Introduction]

- ANI activity is one of the most important functions in ensuring the safety of NPPs. ANI verifies that manufacturing and installation of the safety class components and construction of concrete containment buildings are conformed to the applicable Codes and Standards. In addition to the above activities, ANI confirms the integrity of the safety class components and concrete containment buildings in operating plant through the reviewing of in-service inspection results. ANI issues Deviation and Non-conformance Report(DNR) or Memo or ANI Technical Support to maintain the safety and integrity if non-conformance features are found.

[Contents and Results]

- Authorized Nuclear Inspection for construction of NPPs : Deviation and Non-conformance Report(DNR)(1 case), Issue of ANI MEMO(12 cases), ANI Technical Support(27 cases)

- Authorized Nuclear Inspection for manufacturing and pre/in service : Issue of ANI MEMO(44 cases)

Technical support for KEPIC certificate

[Introduction]

- Domestic nuclear power industry has to follow the KEPIC certification system in order to show its quality assurance ability. Obtaining KEPIC certification is essential for manufacturing and construction companies that provide services to nuclear power industry. Based on abundant knowledge and experience about quality assurance in nuclear power industry, ANID has been conducting various technical support such as QAM(Quality Assurance Manual) approval, authorized nuclear inspection, demo job examination, etc.

[Contents and Results]

- Reinforced quality assurance system in the domestic nuclear power industry through support for obtaining the KEPIC certification

- Established a systematic foundation for NPP export

- 7 organizations have obtained/renewed KEPIC certification due to ANID’s support