R&D | KIMS, transferred ‘extrusion-type ultrafiltration ceramic separator manufacturing technology’ to Finetech Co., Ltd.

Page info

Date23-02-09 17:51 Hit407Link

Contents

Starting the localization of ceramic membrane for the extreme environment! |

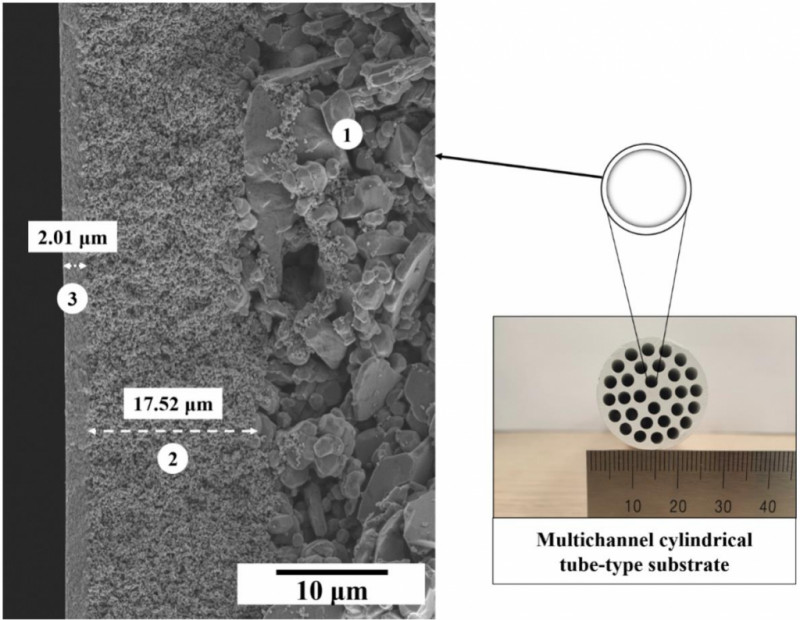

A research team led by Dr. In-Hyuck Song of the Ceramic Materials Divison of the Korea Institute of Materials Science (KIMS), a government-funded research institute under the Ministry of Science and ICT, developed ‘ultrafiltration class ceramic membrane manufacturing technology by ceramic extrusion process and sol-gel coating process’ and transferred the technology to Finetech Co., Ltd. (CEO Seok-joon Jang).

The technology transferred this time is ‘ultrafiltration ceramic membrane manufacturing technology with a pore structure of 10-nanometer class’. Common polymeric membranes have the disadvantage of limited application range due to their low thermal and chemical stability. However, the ceramic membrane developed by KIMS is a new extruded membrane compensating for all these disadvantages. It was developed to supply industrial water required throughout the entire manufacturing process to the target water quality with the primary goal of wastewater treatment for the semiconductor/electronics industry. Contaminants and waste sludge from the CMP process, which are difficult to remove with existing water treatment technologies, can be effectively removed using a 10-nanometer class ceramic membrane. In the future, as alternative technologies such as distillation, adsorption, and extraction, as well as general water treatment, the scope will be expanded to markets that require various extreme operating conditions such as semiconductors, pharmaceuticals, food, paper, and power generation in high temperatures, high pressures, acids/bases, organic solvents environments.

Through this technology transfer, Finetech Co., Ltd. plans to localize technologies led by foreign companies, develop new products, and gradually expand its market share at home and abroad, focusing on reliability, eco-friendliness, mass productivity, and efficiency. It is striving to increase sales by securing initial market share and target market expansion through ceramic membrane marketing expansion and aims to establish a mass production line in 2025.

Principal researcher In-Hyuck Song, who is in charge of the research, said, “It is very meaningful that we developed the original technology for manufacturing 10-nanometer class ceramic membrane and opened the possibility of commercialization.” He continued, “We expect that it will be applied as an element technology to be used in various strategic core areas such as chemical, bio, pharmaceutical industries, and resource recovery as well as industrial and domestic wastewater in the future.”

This technology was developed with the support of the detailed project of the National Core Material Research Center for the Nano and Material Technology Development Program of the Ministry of Science and ICT, ‘Development of reactive filtration materials working in an extreme environment for wastes from semiconductor/electronic industry (KIST, Director So-Hye Cho)’.