R&D | KIMS developed Korea’s first plasma-resistant nanocomposite ceramic with new composition and its processing technology.

Page info

Date23-03-27 12:30 Hit248Link

Contents

Localizing the ceramic parts used for the semiconductor etching process! |

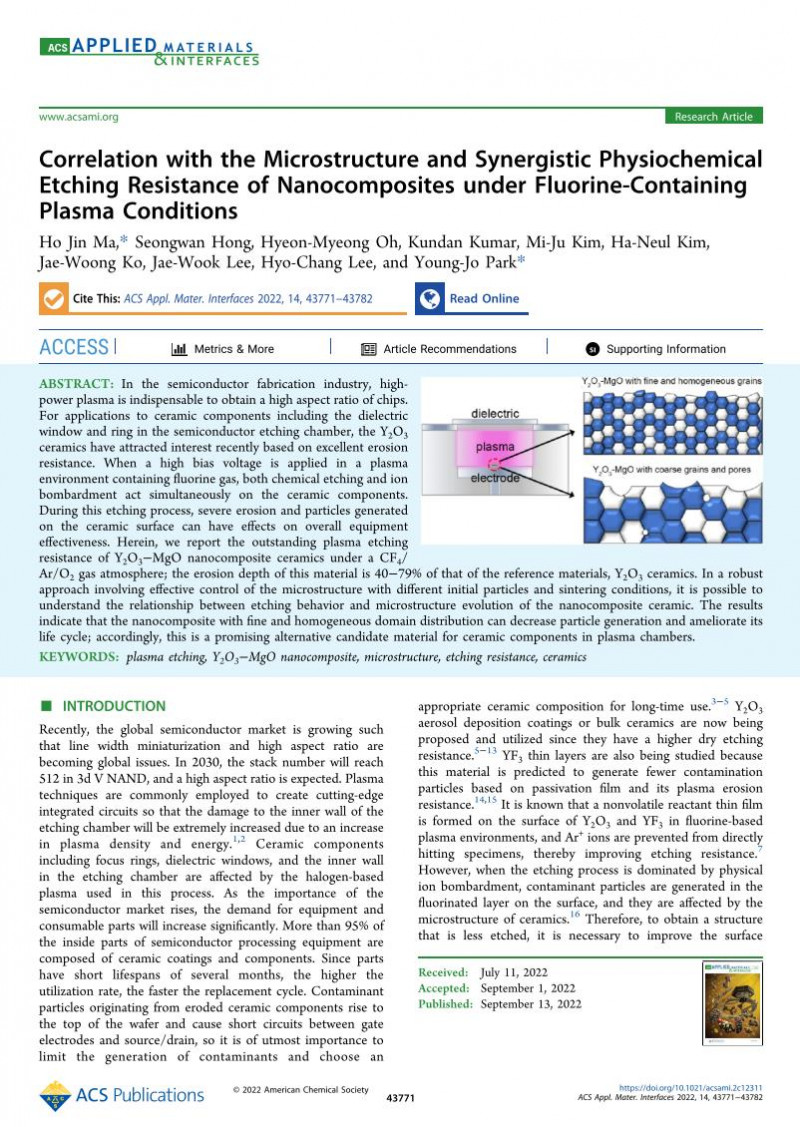

A research team led by Dr. Ho Jin Ma and Dr. Young-jo Park of the Department of Engineering Ceramics at the Korea Institute of Materials Science(KIMS), a government-funded research institute under the Ministry of Science and ICT, succeeded in developing Korea’s first plasma-resistant nanocomposite ceramic with new composition and its processing technology, which reduces contaminant particles inside semiconductor manufacturing equipment.

Generally, plasma etching is used in production of semiconductor device. The silicon wafer as well as the internal parts of the production equipment are exposed to plasma and contaminant particles are generated during this process, which frequently causes chip defects. As a result, ceramic parts, which account for more than 90% of the internal materials of the equipment, are frequently replaced, which is a major cause of hindering productivity.

The research team used nanocomposite rather than conventional single-component ceramics to synthesize 10-nanometer-sized yttria-magnesia (Y2O3-MgO), and obtained 100% dense material through closed-pore, dense composite sintering process. A low etching rate is used as a basis for determining the quality of a material. The etching rate of the developed nanocomposite was only 6.5% compared to sapphire and 40% compared to yttria (Y2O3) which is known to have the best plasma resistance.

In addition, by analyzing the change on the surface after plasma etching according to the grain size and porosity in the microstructure of the nanocomposite, the researchers confirmed that nanocomposite with a fine and uniform microstructure resulted in excellent etching resistance and decreased surface roughness.

Dr. Ho Jin Ma, a senior researcher at KIMS, said, “More than 90% of the etching process in the entire semiconductor process is occupied by the US and Japanese equipment and parts, and China is quickly catching up. This research outcome is a representative case of developing world-class plasma-resistant materials with domestic technology, and at the same time, will become a cornerstone for the localization of parts.”

The research was funded by the Nano/Material Technology Development Program (National Core Materials Research Group) of the Ministry of Science and ICT. KIMS transferred the related technology to Mactech (CEO Byeong-Hak Kim). Through joint research with Dr. Hyo-chang Lee's research team at the Korea Research Institute of Standards and Science, the research was published in ACS Applied Materials & Interfaces (IF: 10.383), an international academic journal published by the American Chemical Society (ACS) on September 22, 2022.