None R&D | A Research Team, Headed by Dr. Cheol-woo Ahn, Earns Recognition as ‘100 National Excellent R&D Performance’

Page info

Date23-11-21 13:44 Hit139Link

Contents

|

The research achievement of the Korea Institute of Materials Science (KIMS), a government-funded research institute under the Ministry of Science and ICT, was selected as the‘100 National Excellent R&D Performance in 2023.’The selected technology is ‘the KIMS MgO(Magnesia) new heat-dissipation material’ developed by Dr. Cheol-woo Ahn’s research team from the Department of Functional Ceramics in the Ceramic Materials Division.

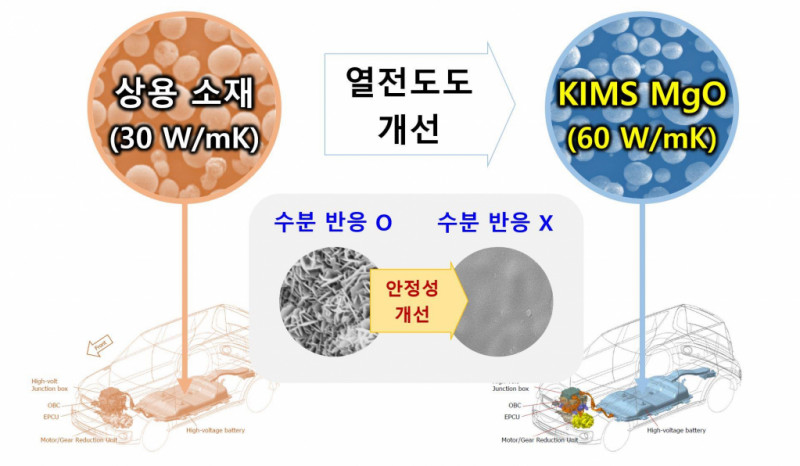

Although MgO exhibits excellent heat-dissipation performance, it has not been widely utilized as a heat-dissipation material due to manufacturing challenges and its tendency to react with moisture in the air. In contrast, KIMS MgO will be employed for battery thermal management to prevent electric vehicle fires, This is feasible because it can be easily manufactured at low temperatures and does not react with moisture in the air.

As the demand for electric vehicles gradually increases, there is a growing need for high-performance heat dissipation materials in electronics, including batteries, to enhance the safety of electric vehicles. The KIMS MgO material, priced comparably to commercial alumina (which currently dominates over 90% of the ceramic heat-dissipation filler market, with a thermal conductivity of 20~30W/mK), boasts more than twice the heat dissipation performance. The research team has developed the KIMS MgO material to be manufactured using the most cost-effective ceramic manufacturing process available. This process involves a heat treatment process by adding a very small amount 0.2% of additives to standard MgO, As a result, it can be easily manufactured and commercialized using existing equipment within the ceramic industry.

The Department of Functional Ceramics at KIMS initiated the development of future heat management materials as part of an institute-wide fundamental project in 2015. Currently, they are actively engaged in the development of various heat management materials, notably KIMS MgO. The inception of the KIMS MgO material traces back to the original research on heat dissipation ceramic materials undertaken in a fundamental project at KIMS. The successful commercialization of this material was achieved through the establishment of a research spin-off company, SOULMATERIAL. Presently, the department is dedicated to ongoing research for the further advancement of heat dissipation materials. They are also working towards expanding the application of these materials to a diverse range of products and markets, which includes MgO crucibles.

Dr. Cheol-woo Ahn, a principal researcher at KIMS, said, "I think it's significant that we've been recognized as the only material in the world that has completely solved all the problems of MgO material that even the leading Japanese companies haven’t solved.”and added, "We will continue to do our best to make Korea a leader in the heat dissipation ceramic materials market."

Meanwhile, the‘100 National Excellent R&D Performance’ is a program in which the government selects outstanding national research and development achievements to enhance public awareness and interest in the pivotal role of science and technology in driving national development, The aim is to inspire pride among scientists and engineers. The 100 National Excellent R&D Performance has been selected and announced every year since 2006.