Department of Magnesium

- Head of Department

Kim, Young-min

Department Introduction

Department of Magnesium has been developing key technologies for high-performance and high value-added magnesium (Mg) alloys as the lightest structural metal. We focus on the development of alloy design and manufacturing process technologies such as non-flammable and stainless materials, high-strength materials for casting and extrusion, high-formability sheets, and biodegradable metals. Through this, we strengthen cooperation with various domestic and foreign institutions and companies for practical applications and promotion of Mg material and parts industry.

Major Activities

- Building demonstration platform through Mg material for transportation equipment construction project

- 6 SCI/E, applied and registered 2 domestic and foreign patents, 20 million KRW in technology fee for high-strength, corrosion-resistant and nonflammable Mg alloy

- 1 foreign patent registration related to grain refinement technology of Mg alloy

- 1 domestic patent registration for high corrosion-resistant Mg sheet with superior room temperature formability

- 1 foreign patent registration related to handling release device and method

- 2 domestic and foreign patents applications for high-strength, corrosion-resistant and biodegradable Mg alloy

Major Research Area

- Design and development of multi-functional non-flammable Mg alloy and its application technology

- High-strength, corrosion-resistant, and biodegradable Mg alloy and manufacturing technology

- High-strength Mg alloy for casting and manufacturing technology

- Rolling and extrusion technology for manufacturing parts for weight reduction of transportation equipment

- Recycling technology of scrap and waste parts of Mg alloy

- Advanced materials based on intermetallic compounds with room temperature ductility and exploration of their properties

- Real-time analysis technology of microstructure change of metals using synchrotron

Future Research Plan

- Development of low-carbon manufacturing process technology for carbon neutrality

- Development of commercial system for recovery of useful resources from Mg/Li series waste parts

- Development of ultra-precise biodegradable Mg tube manufacturing technology for vascular disease treatment

- Development of fixed Mg-based hydrogen storage alloy design and manufacturing technology

- Development of structural Mg material and parts manufacturing technology for light weight of next-generation transportation equipment

- Establishment and operation of Mg demonstration platform through ultra-lightweight Mg material complex development project

Major R&D Activities

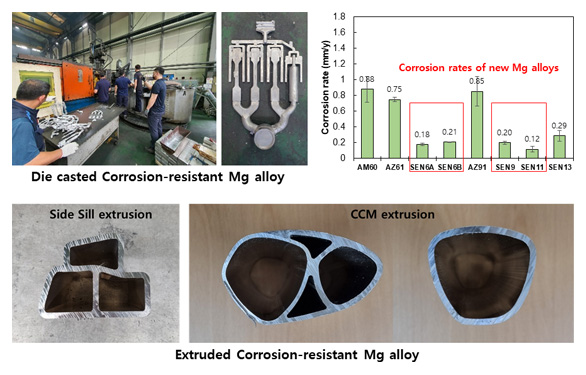

Development of high-strength and corrosion-resistant Mg alloys for casting and extrusion application

- Development of ultra-high corrosion-resistant Mg alloy for die casting through addition of RE elements

- Application of high corrosion-resistant Mg alloy for automobile side sill and CCM product

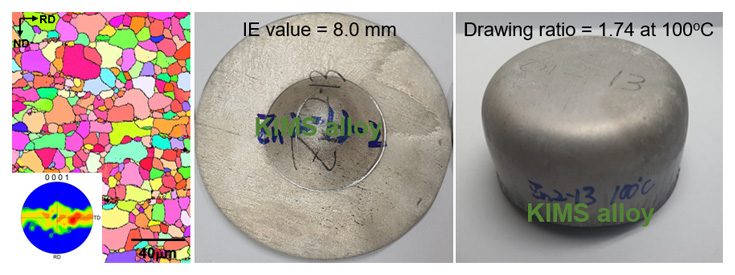

Development of high corrosion-resistant and high-formable Mg sheets and low-cost manufacturing technology

- Development of high corrosion resistant Mg alloy sheets having high stretch formability and durability

- IE value = 8.0mm, LDR > 1.74@100oC, corrosion rate < 0.4mm/yr - Simultaneous improvement of mechanical and corrosion properties through the optimization of thermo-mechanical treatment

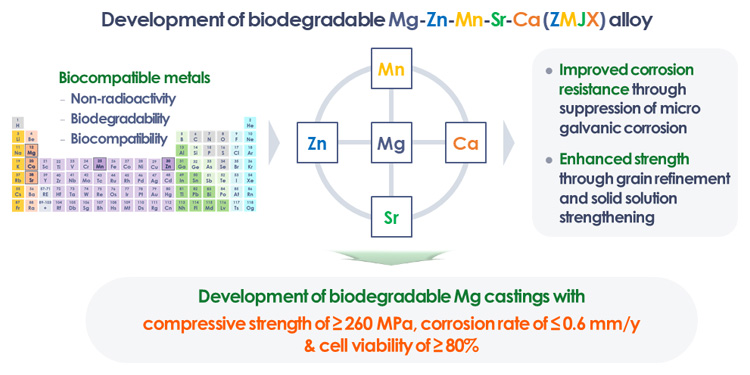

Development of control technology for biodegradable metals with high strength and high corrosion resistance

- Development of high-strength and corrosion-resistant Mg alloy for biomedical application and its manufacturing technology

- Development of biodegradable Mg castings with a compressive strength of 260 MPa or more, a corrosion rate of 0.6mm/y or less, and cell viability of 80% or more